|

| |

JP powerbox vs seal

|

it didn't look so bad in

the board, with "just a little crack below the head of the fin screw -

couldn't you just squirt a little Epoxy in there?"

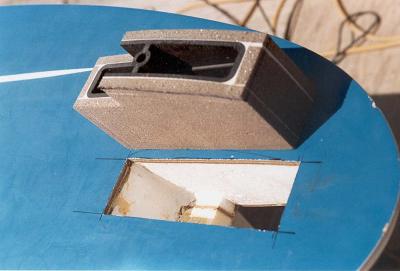

uh - let me see: roof of fin box cracked, sides

delam'd, fin pushing against 1/8" Divinycell with a bit of glass on each

side.

Answer: I think not! |

|

New Chinook box set into

3/8" Divinycell. Old box cut out. Observe the step-down in order to not

jeopardize the foot strap inserts just above.

Fit is snug, so that the new box bears against

bottom and deck for maximum support. |

|

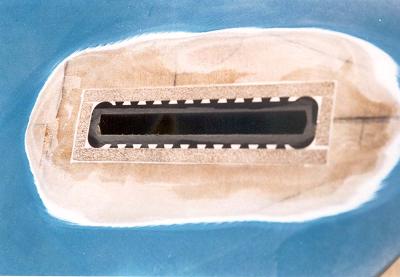

New box installed into

board with a slurry of Q-Cells and milled fibers in slow Epoxy. The face

of the box needs to be exactly flush, so that the fin head will sit

flush later.

I check for square with the longest fin I have. |

|

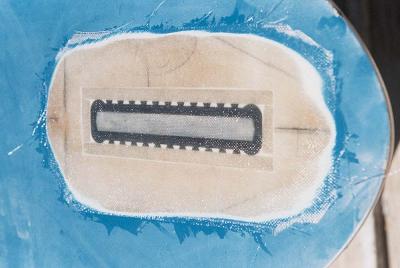

After sanding through

the original outer glass just down to the Divinycell, and the face of

the fin box just to the bottom of the molded-in sanding guides

(thank you, Chinook!), I laminate over with whatever glass I found there

originally, in this case 3x 4oz cloth. The first layer is 1in wider than

the fin box cartridge, the second layer about 2in wider, and the third

one about 3in wider all around to create a gradual transition to the

original laminations. |

|

Same procedure on deck,

except that after trimming, the top fin box cavity needs to be filled -

I use EPS foam bits, capped by 1/4" Divinycell

Note the fin screw support tube! This design

eliminates the possibility of wobble that all the recessed fin screw

designs have. |

|

Glassed over with like

materials, except that I add 3 or 4 small bits of glass over the fin

screw support tube, since that is where the washer will come to bear. |

|

After feathering out

the fiberglass, I apply an Epoxy fairing compound (shown is VC Watertite

by Interlux). This smoothes over bumps and such, and fills the

weave of the fiberglass. |

|

A little sanding, a

little primer, a little paint, re-apply the pad, re-apply some non-skid

(even though I seriously doubt the wisdom of having non-skid back there

- personally, I never stand there - at least not intentionally, but I do

drag my booms across that bit of aft deck - whatever...)

and - tada!

oops, almost forgot to drill the fin screw hole...

been there, done that |

|

back to Repair Menu |

|