|

| |

Ultimate Challenge: The Snap

| Putting a snap back

together is more than an exercise in reassembly of two short bits into one

more agreeable, long one. Original flex characteristics want to be

preserved, and the weight kept as close to the original as possible. All of

this without creating hard spots, which would only lead to further snaps.

And of course, it all needs to look purdy. The

following is my current procedure, evolved from about 90 snap repairs to

date, of which (2) came back. Both of those had snapped again. Both snapped

more than 3ft from my repair.

Instead of introducing stringers and broomsticks and

such, I simply rebuild the structure with materials as close to the original

construction as possible, using long scarph joints everywhere, with long,

staggered overlaps of the reinforcements, in order to create as smooth a

transition as possible from the original lamination to the new. Of course,

all Divinycell gets vacuum-bagged, in order to insure perfect adhesion.

Done this way meticulously, taking great care to fair

every intermediate step, will add 1/2 to 1oz to a shortboard, and up to 2oz

to a longboard. All the feedback I have received confirms that these snap

repairs ride very much like the originals. As a matter of fact, I have a

waiting list of folks anxious to purchase refurbished snaps. |

|

a large rider had ignored a major deck

indent for too long, causing the deck to buckle and the board to snap. The

deck had failed in compression, with the EPS core squooshed together at deck

level. The outer fiberglass laminations had peeled a bit, but not

excessively so. The board was otherwise in fine

shape, without any additional structural dings, so that reconstruction was a

very viable choice. |

|

Parts reassembled on a rocker jig, with

considerable tension created deck and bottom via these very high-tech

"Spanish Windlass" tensioning devices. This tension will help to perfectly

align the bits, and minimize the amount of fill needed, i.e. keep weight

gain to a minimum. With everything under

tension, I inject rigid Marine Urethane foam, to help hold the bits aligned,

and to seal the structure for future vacuum-bagging. |

|

Once the Urethane foam has set, I clamp

the board to a jig, and bevel-grind the deck to sound material, removing

everything that has been crushed, delam'd and otherwise compromised in any

way. The EPS core gets filled as needed, to create a smooth sub-strate for

the inner structural laminations. All

tensioning devices stay in place throughout these manipulations, since the

Urethane foam is not of the strongest... |

|

Preparations for the vacuum-bagging of

the inner glass and Divinycell (or rather, in this case, Herex cross-linked

PVC), with all ingredients pre-cut, marked, and sorted in the order they

will be needed. |

|

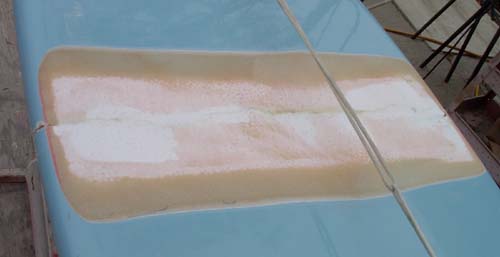

Inner glass & and PVC foam in place with

the slowest Epoxy I have (West System 105 resin with 206 hardner). Peel ply

and breather fabric cover the Herex, to evenly distribute the vacuum.

Pressure is about 6inHg. (and immediately after

taking this picture, I flipped the board over, in order to prevent

accelerating the Epoxy cure and creating harmful exothermic heat) |

|

The bottom is then prepared the same way

as the deck. Tensioning devices still in place, until there are balanced

structural laminations on both deck and bottom. |

|

Herex and inner glass vacuum-bagged to

bottom, then feathered out. Adjacent paint and primer removed, and the

original laminations bevel-ground, in order to achieve a gradual transition

to the new laminations. |

|

New fiberglass in place deck and bottom.

I overlap each layer on the rails, just like the factory does originally. |

|

Fiberglass ground, filled with an Epoxy

fairing compound, then sanded smooth. See how little filler is required! |

|

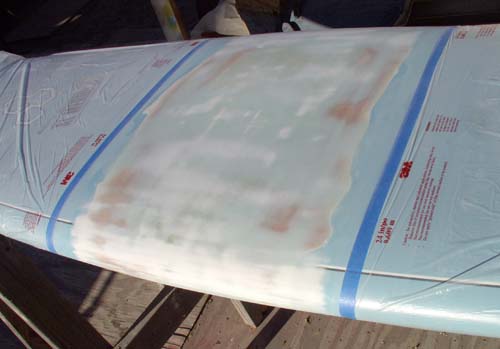

Deck faired, then primed, then most of

both fairing compound and primer sanded off again. At this point, with your

eyes closed, your hand would not find any bumps.

I tape off the rest of the board with pre-taped masking

film. Extravagantly expensive, but a wonderful time saver! |

|

LP applied, sanded and polished, then

pinstripes touched up. Not so bad - for a

Kraut... Thanks to Bill S for

providing the model for this pictorial! |

|

a PS: about one year after the above snap repair, this

board just came back to me with a busted FCS insert. It had in the meantime

been to Fiji and to Hawaii, and been surfed regularly in its home waters.

The snap repair is as good as the day it first left here. Serious

shoulder-clapping time! |

|

PPS: another 1 1/2 years later, it just came back with a

mashed nose. Snap repair still good as new, customer happy, I happy - yeah! |

|

back to

Repair Menu |

|