| |

Softop Snaps

or "you mean I gotto get off before I

hit the beach??"

| As stoutly as Softops

are built, they come to me snapped more often than any other type of

board. I suppose its because they are primarily used by novices; and

they are frequently used and abused as rentals.

More often than not, there is evidence of impact

on the tip of the nose, and a buckle or snap 2ft there"aft"er. Such as

this one: |

|

near-new rental board, the shop

owner nearly in tears, the nose neatly severed - it must have been a

hard impact indeed, to have caused such a straight forward snap without

any significant delam! |

|

Dry-fitting the bits - during a

violent event such as a snap, edges get pushed and shoved ever which

way, so that they won't go back into their appointed places without some

adjusting, i.e. cutting back with a utility knife. As hard as I try to

initially save as much of the original structure as possible to help

with the alignment, I usually end up cutting away a fair amount of

stuff, to allow the rest to properly fit together. |

|

After taking things apart again and

meticulously removing all loose bits, the two halves are clamped

securely to a rocker jig, the bottom of the joint taped over (one of the

few good applications around boards for Duct Tape!), and Marine Urethane

foam injected to "set" the joint and replace any chunks that may have

been lost in the accident. |

|

Once the Urethane foam has set (I

prefer to "let it rest" overnight, lest there is interaction with

subsequent building materials), I re-clamp and grind away all loose

and/or superfluous stuff on the bottom, then bevel-grind the adjacent

fiberglass laminations. Overall panel thickness is vastly less than in

Tuflites, so it takes a bit of practice to get a consistent bevel

without digging into the soft foam nearby. |

|

Whatever divets and crevices (plus

little grinder slips) are filled with an Epoxy/Q-Cell paste (the slow

variety, of course!), to create a smooth substrate for the fiberglass

laminations. Big Softops have up to 20oz of fiberglass in their skins,

plus extra reinforcement on the rails, so I apply (5) layers of 4oz

cloth, well-staggered, lapping over the turn of the rails, plus add (2)

additional patches on the rails, since a lot of fairing happens there

and some losses are likely. |

|

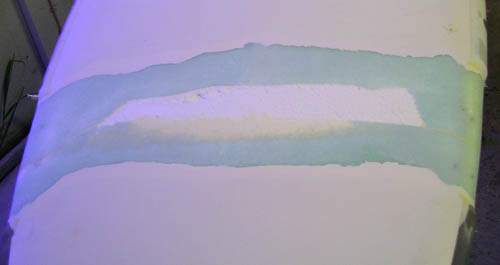

Repeat on deck, with all layers

wrapping the rails, so that all told, we end up with twice as much glass

on the rails as on the flats - which is the way they come from the

factory.

see the graffiti emerging? cute! |

|

Edges of the EVA padding are cut

nice & tidy & parallel, superfluous stuff scraped away with a

single-edged razorblade. Laminations are feathered out and faired with

VC Epoxy fairing compound.

I always feel like a voyeur when I uncover such

scribbles. Left by the Thai builders, they felt certain that their

graffiti would be forever covered up. |

|

Deck & bottom faired and primed, the

new piece of EVA padding is installed. Cut a smidge longer fore & aft

than the available space, and to generously go around the rails and

thensome, it is applied with the flammable type of contact cement,

rolled down with vigor, and the edges "set" by pounding them with a

mallet.

Lest you tear or otherwise maul your handiwork,

nothing but a brand-new blade in the utility knife will do to trim the

edges of the EVA! |

|

With the

sander rotating into the edge of the EVA pad, the new bit is

beveled to conform to the angle of the original padding. Any other

direction will tear your spanking new pad and force you to start over

again! frustrating, that!!

The primer is sanded down in preparation for the

bottom paint. |

|

With the edges of the EVA securely

taped off - the inexpensive, beige tape seems to stick the best, and it

helps to have thoroughly cleaned the EVA prior (I use a soft eraser for

this job) - and anything within 3ft of the repair covered or taped off,

the bottom gets painted. Even though newer Softops have a plastic skin

over their fiberglass, it seems to work well to just paint over it all,

as long as it is a decent paint - I use 2-pack LP and have never had to

look back.

Once the paint has tacked, remove the tape. Let

cure over night. Sand the paint's edges with 320 wet & dry paper, then

rub out with a Scotch Purple Pad, to imitate the satiny appearance of

the original finish. |

|

With the patterns getting exotic

even on these lowly Softops, I give up and go for the "contrast band"

look - works for me :) |

|

back to Repair Menu |

|